International Tolerances on Clothing

INTERNATIONAL TOLERANCES FOR CLOTHING

SPECS

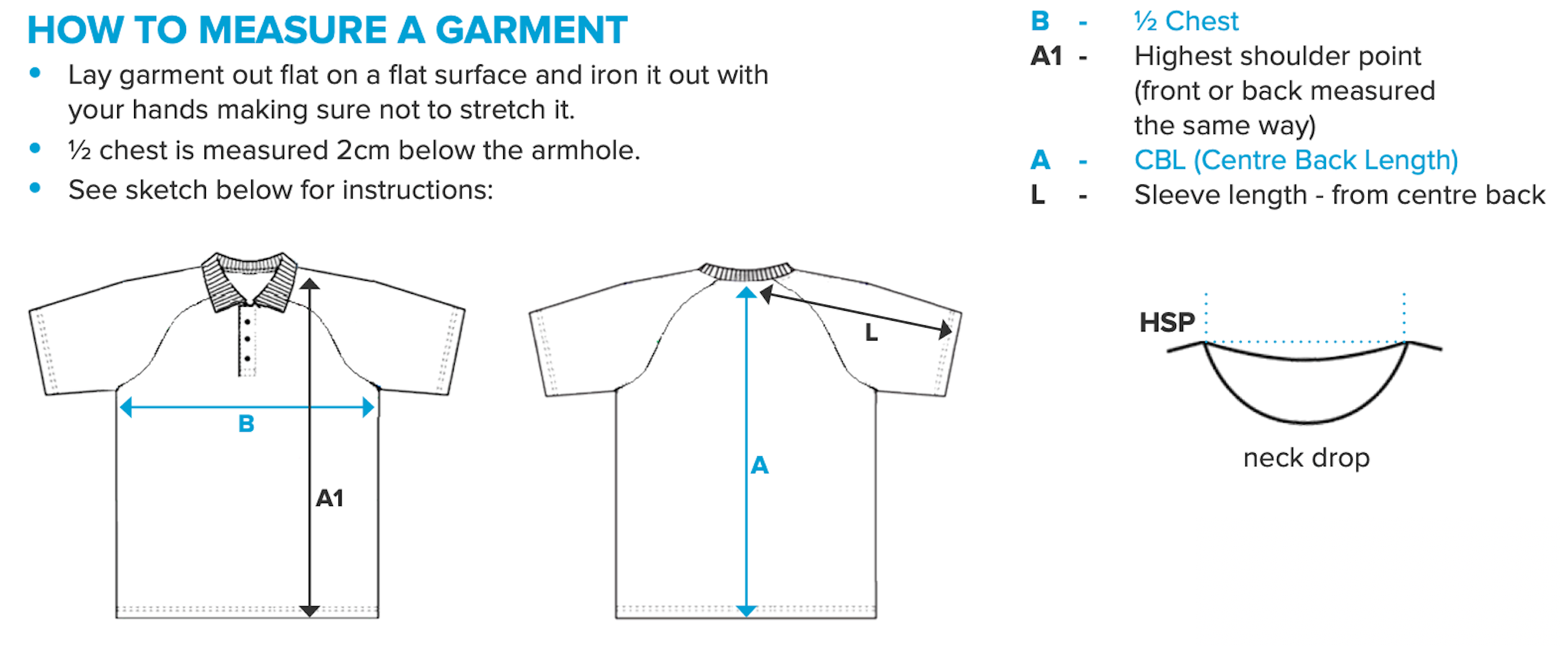

A garment specification sheet or spec sheet is a technical document that contains the construction details of a product, a technical diagram/sketch of the garment and the measurements of a product.

- With our clothing, all the half chest measurements are shown in the catalogue and these are taken from the spec sheet

- The industry norm is a tolerance of 2cm, i.e. 2cm smaller or bigger than the spec.

- For example if the 1⁄2 chest spec is 49cm, it is internationally accepted if the item is 47cm as well as 51cm.

- Although our factories work hard to adhere to the supplies specs, garments are never all 100% according to spec. Some of the reasons for this is that fabric gets layered in many layers before the pattern pieces are cut out and sometimes material shifts slightly during the process, or a machine operator may take a little more seam allowance on a garment. Each garment is sewn individually and as such will vary slightly from one to the other.

SHADE TOLERANCE

-

There are many factors which affect the dyeing process of greige fabric (an unfinished woven or knitted fabric that hasn’t been bleached or dyed) including water in the area, time of the year, temperature, fabric being dyed etc

-

Amrod uses a handful of different factories around the world to produce our items and although we do our best to keep the shading as close as possible from one batch to the next, there may be slight shade variances.

-

Subtle differences can appear between different batches of the same colour fabric dyed by the same manufacturer so centralising the dyeing process would not eliminate this variance.

-

We make use of Lab dips (accepted colour swatches) which are sent to all our factories to ensure that the batch colours are as close as possible.

-

Internationally there is an acceptable shading tolerance of one shade on either side (lighter or darker).

-

While care is taken through the whole dyeing process as well as the lab dips and a number of QC checks during the manufacturing process, it is expected that one batch of a clothing item would vary slightly from the next.